Large Fabric Cutting Board: Self-Healing Mats for Precision

Professional Cutting Surfaces 24×36 to 48×60 Inches for Quilting, Sewing & Crafts

Upgrade your fabric workspace with large cutting boards designed for serious quilters and sewing enthusiasts. These expansive self-healing surfaces accommodate full-width fabrics, multiple pattern pieces, and complex quilt layouts while protecting both cutting tools and work surfaces.

From 24×36 inch standard sizes to generous 48×60 inch studio boards, large cutting surfaces eliminate constant fabric repositioning. The precision grid markings and durable construction transform cutting from tedious task to efficient process, delivering professional results for every project.

Why Choose Large Cutting Boards

Large cutting boards provide workspace advantages impossible with standard sizes. The expanded surface accommodates folded yard goods without overhang, allowing complete visibility of fabric positioning and measurement accuracy.

Quilters benefit enormously from boards that hold entire blocks or multiple strips simultaneously. This eliminates midstream repositioning that can introduce measurement errors or fabric shifting during cuts.

Professional Workspace Benefits

The stable, marked surface ensures fabric remains flat and aligned throughout cutting operations. Grid lines provide instant reference points for squaring fabric, measuring seam allowances, and aligning pattern pieces without additional rulers.

Self-healing materials protect expensive rotary cutters from premature dulling while shielding furniture from cutting damage. The specialized surface absorbs blade action without creating permanent grooves that catch subsequent cuts.

Efficiency Through Size

Large boards reduce project preparation time significantly. Cut multiple garment pieces or quilt blocks in single sessions rather than processing fabrics individually.

The ability to walk around properly sized boards enables natural cutting motions without awkward reaching. This ergonomic advantage reduces fatigue during marathon cutting sessions. Browse our complete quilting supplies for complementary equipment.

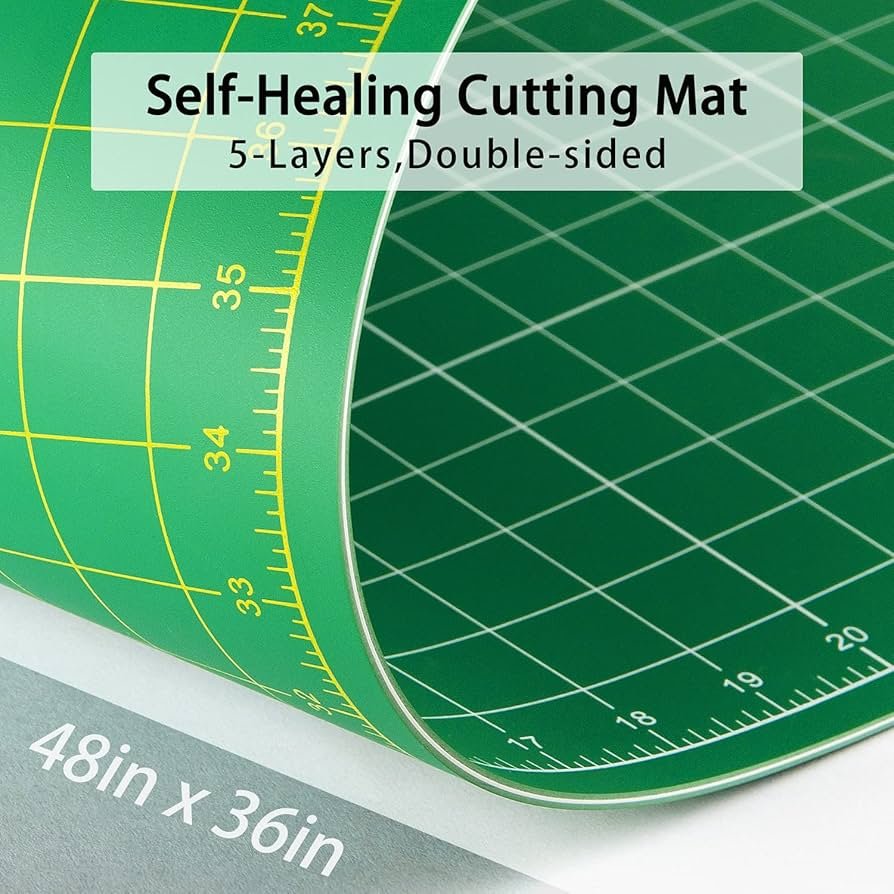

Extra-Large Self-Healing Cutting Mat 36″ x 48″

Professional-grade double-sided cutting board featuring premium 5-ply construction for maximum durability. The generous 36×48 inch surface accommodates full fabric widths and complex quilt layouts while precise grid markings ensure accurate measurements every time.

- 36″ x 48″ extra-large cutting surface for studio use

- 5-ply self-healing construction extends mat lifespan

- Double-sided design with contrasting grid colors

- Clear measurement markings in inches and centimeters

- Non-slip backing prevents movement during cutting

- Protects rotary blades and work surfaces

- Ideal for quilting, sewing, and large craft projects

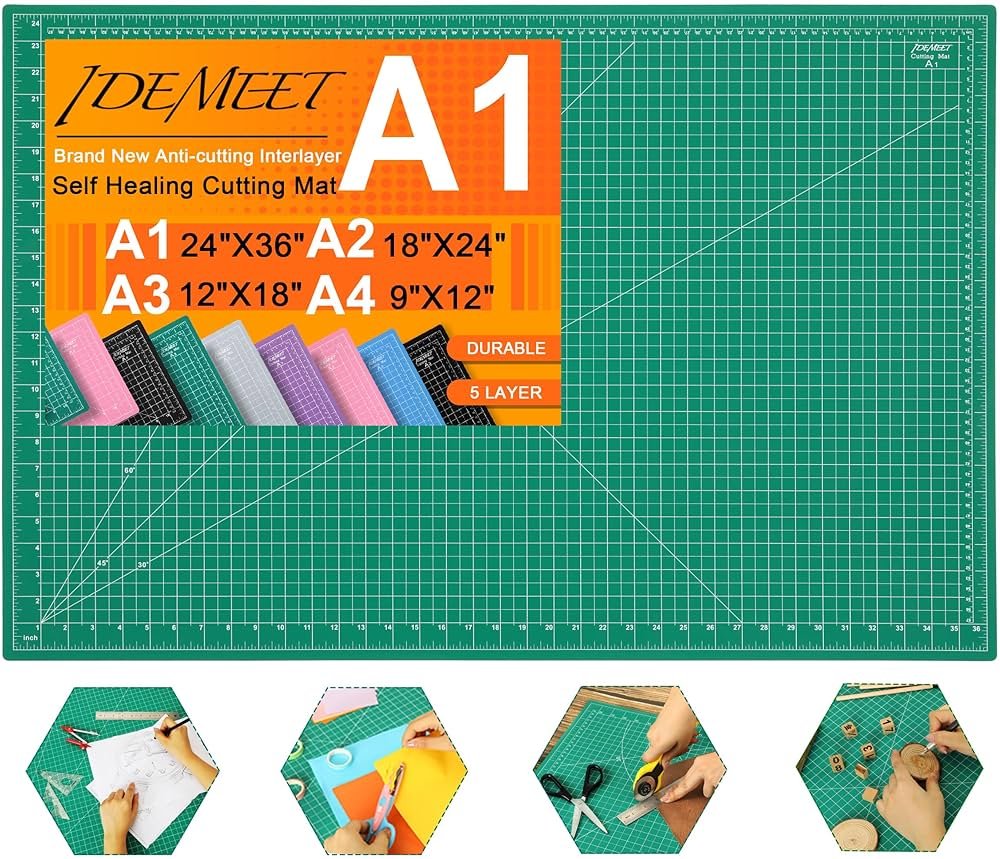

Large Self-Healing PVC Cutting Mat 24″ x 36″

Versatile large cutting board combining professional performance with practical sizing. The 24×36 inch surface provides ample workspace for most quilting and sewing projects while remaining manageable for home studio storage.

- 24″ x 36″ size balances workspace with portability

- Premium PVC self-healing surface protects blades

- Gridded layout with multiple angle markings

- Double-sided for extended use and versatility

- Soft cutting surface won’t damage rotary cutters

- Perfect for fabric, quilting, sewing, and scrapbooking

- Durable construction for years of reliable service

Understanding Size Options

Large cutting boards typically range from 24×36 inches to 48×60 inches or beyond. Each size serves specific workspace needs and project types.

Standard Large Boards (24×36 to 24×48 inches)

These dimensions suit most home sewers and quilters, accommodating folded yard goods and multiple pattern pieces. The 24-inch width fits comfortably on standard tables while 36-48 inch lengths provide generous working area.

This size range offers excellent balance between functionality and storage practicality. Most crafters find these dimensions sufficient for regular quilting blocks, garment pattern pieces, and general fabric cutting tasks.

Extra-Large Studio Boards (36×48 inches and larger)

Serious quilters working with large blocks or professionals requiring maximum workspace choose boards measuring 36×48 inches or greater. These expansive surfaces accommodate entire quilt layouts or multiple garment pieces simultaneously.

Consider available workspace carefully before selecting extra-large boards. These require substantial table surfaces and dedicated storage when not in use. Also explore our standard cutting mats for comparison.

Workspace Considerations

Measure your crafting area before purchasing. Ensure adequate clearance around the board for comfortable movement and access from multiple sides when possible.

Some quilters position large boards on kitchen islands or dedicated cutting tables at comfortable standing height. This ergonomic approach reduces back strain during extended cutting sessions.

Self-Healing Materials Explained

Self-healing cutting boards feature multiple compressed layers of vinyl or synthetic materials that separate when cut, then naturally compress back together. This remarkable property allows thousands of cuts without permanent surface damage.

Construction Quality

Premium boards utilize 3-ply to 5-ply construction for optimal durability and healing capacity. Multiple layers provide stability against warping while enhancing the self-healing effect.

The slightly cushioned surface allows rotary blades to penetrate just enough for clean cuts without excessive blade wear. This balance protects both mat and cutting tools throughout extended use.

Material Thickness

Large cutting boards typically measure 2mm to 3mm thick, with premium versions reaching 5mm. Thicker materials resist warping better, particularly important for larger boards where edge curling becomes problematic.

Increased thickness also improves the self-healing capacity, allowing the material to close back together more effectively after repeated cuts in the same area.

Pro Tip: Store large cutting boards completely flat, never rolled or leaning. Heat and direct sunlight cause warping, so keep boards in climate-controlled spaces away from windows and heating vents.

Grid Markings and Measurement Features

The measurement systems printed on cutting boards distinguish functional tools from simple protective surfaces. Look for clear, comprehensive markings that won’t fade with regular use.

Essential Grid Features

High-contrast grid lines in one-inch increments provide basic measuring capabilities. Many boards include half-inch markings for greater precision during detailed work.

Premium boards feature both imperial and metric measurements, accommodating quilters working with international patterns. Angle lines at 30°, 45°, and 60° assist with triangle cutting and bias strips.

Specialized Markings

Quilting-focused boards often include printed squares in common sizes (2.5″, 3.5″, 4.5″) for quick accuracy checks. Circle templates, diameter guides, and corner radius markings expand cutting possibilities.

Border measurements around mat edges provide quick reference without rulers. These perimeter markings prove especially useful during strip cutting and border preparation. Pair with quality fabric scissors for complete cutting solutions.

Color Selection and Visibility

Cutting board color significantly affects visibility and user experience. The surface color provides background contrast that makes fabric edges and markings clearly visible.

Standard Color Options

Green remains the traditional choice, offering good contrast with most fabric colors. The medium tone shows both light and dark fabrics clearly without color distortion during fabric matching.

Gray and charcoal options provide neutral backgrounds that don’t influence color perception. These prove particularly valuable when matching fabric shades or working with subtle color variations.

Double-Sided Advantages

Many large boards feature different colors on each side, typically green/black or gray/black combinations. This versatility allows choosing optimal background contrast based on fabric being cut.

Flip the board to find better visibility rather than struggling with poor contrast. The dual-color design effectively doubles board utility without additional storage space.

Storage Solutions for Large Boards

Large cutting boards present storage challenges due to their size. Creative solutions maintain board flatness while managing space constraints.

Flat Storage Options

Slide large boards under beds, behind furniture, or in dedicated flat storage between cutting tables and walls. Maintain horizontal positioning to prevent warping from vertical pressure.

Some crafters create custom slots between wall studs for flush storage that utilizes otherwise wasted space. This approach keeps boards accessible while maintaining proper flat storage.

Vertical Solutions

When vertical storage proves necessary, use full-length support across the entire board height. Wall-mounted racks with complete backing prevent pressure points that cause warping.

Never lean boards against walls at angles or support them at single points. Uneven weight distribution over time creates permanent bowing that affects cutting accuracy.

Foldable Alternatives

Some manufacturers offer foldable large boards with hinges allowing compact storage. These maintain flat surfaces when opened but fold to half or one-third size for storage.

The trade-off involves fold seams that may slightly affect cutting across junctions. Higher-quality designs minimize this issue through precision engineering and smooth hinge construction.

Maintenance and Care

Proper maintenance extends large cutting board lifespan significantly. Simple care routines protect your investment while maintaining precision and self-healing properties.

Regular Cleaning

Remove fabric lint and thread debris with soft brushes after each use. For deeper cleaning, use mild soap solutions with room temperature water applied with soft cloths.

Never soak boards or use hot water, which can affect material composition and self-healing capacity. Rinse minimal water across surfaces and air dry completely before storage.

Preventing Damage

Avoid exposing boards to extreme temperatures or direct sunlight. Heat causes warping while UV exposure fades measurement markings and breaks down self-healing materials.

Rotate cutting areas regularly rather than concentrating all cuts in central zones. This distributes wear evenly across the surface, maximizing functional lifespan.

Surface Rejuvenation

When boards show accumulated cut marks, gentle cleaning with water and white vinegar solution can help restore self-healing properties. This treatment encourages compressed fibers to relax and close existing cuts.

Quality large boards typically last 5-7 years with regular use when properly maintained. Premium versions with thicker materials may serve effectively for 10+ years.

Complementary Cutting Tools

Large cutting boards work best when paired with appropriate cutting implements and accessories. The right tool combinations optimize both efficiency and precision.

Rotary Cutting Systems

Large boards pair perfectly with rotary cutters for smooth, continuous cuts across extended fabric lengths. The self-healing surface protects blades while providing stable foundations for ruler-guided cutting.

Standard 45mm rotary blades handle most tasks, though 60mm blades excel at cutting through multiple layers on large surface areas. Keep replacement blades readily available for consistent performance.

Measuring and Marking Tools

Long quilting rulers (24″ or longer) complement large boards for extended straight cuts. Clear acrylic rulers with non-slip backing stay positioned during cutting without shifting.

Use fabric marking tools and measuring tapes alongside board markings for comprehensive measurement solutions. Pattern weights hold fabric flat without distorting during cutting.

Professional vs Home Use Considerations

Professional sewers and serious hobbyists have different requirements when selecting large cutting boards. Understanding these distinctions guides appropriate choices.

Professional Requirements

Production sewers and teaching quilters benefit from extra-large boards (36×48″ or greater) that accommodate multiple projects simultaneously. Thicker materials (3-5mm) withstand heavy daily use without premature wear.

Professionals often choose premium boards with comprehensive measurement systems and longest available warranties. The higher initial investment delivers value through extended lifespan and superior performance.

Home Crafter Needs

Hobby sewers typically find 24×36″ boards sufficient for most projects while remaining manageable for home storage. Mid-range quality levels provide excellent functionality without professional-grade pricing.

Consider project frequency when selecting quality levels. Regular weekly use justifies premium materials while occasional crafting may work well with standard quality boards. Explore our sewing supplies for complete equipment options.

Frequently Asked Questions

Cutting boards measuring 24×36 inches or larger qualify as “large” for quilting purposes. This size accommodates folded yard goods and multiple quilt blocks simultaneously. Serious quilters often prefer 36×48 inch boards that handle full fabric widths without repositioning, though these require substantial workspace and storage areas.

Store large mats completely flat in climate-controlled spaces away from heat sources and direct sunlight. Never roll, fold, or lean boards vertically without full-length support. Avoid hot water during cleaning and don’t leave boards in vehicles where temperature extremes occur. Proper storage prevents the warping that affects cutting accuracy.

Only fold cutting boards specifically designed with hinges for this purpose. Standard large boards must never be folded as this causes permanent creasing and material damage. Foldable boards sacrifice some cutting precision at fold lines but offer practical storage solutions for space-limited areas. Always verify folding capability before attempting to fold any board.

Look for large cutting mats measuring 3mm or thicker for optimal durability and warp resistance. Boards in 24×36 inch sizes work well at 2-3mm, while extra-large 36×48 inch boards benefit from 3-5mm thickness. Thicker materials provide better self-healing properties and resist edge curling that commonly affects thinner large-format boards.

Quality self-healing boards last 5-7 years with regular home use when properly maintained, while premium versions may serve effectively for 10+ years. Professional heavy use typically requires replacement every 3-5 years. Lifespan depends on cutting frequency, blade sharpness, pressure applied, and maintenance quality including proper storage and cleaning.

Double-sided boards offer excellent value by effectively doubling usable surface area. The contrasting colors on each side allow choosing optimal background for different fabric colors, improving cutting visibility and accuracy. This versatility proves particularly valuable for quilters working with varied fabric palettes without requiring additional storage space.

Large self-healing boards work well for paper crafts, scrapbooking, leather cutting, and general crafting projects requiring measured cuts and surface protection. However, use dedicated boards or sides for non-fabric materials as different substances affect surface wear differently. Paper and cardstock dull blades faster, so avoid returning paper-dulled blades to fabric cutting.

Related Resources

- Quilting Supplies – Complete quilting tools and equipment

- Rotary Cutters & Mats – Comprehensive cutting systems

- Standard Cutting Mats – Smaller mat options

- Fabric Scissors – Precision cutting tools

- Sewing Supplies – Essential sewing equipment

- Measuring Tapes – Accurate measurement tools

- Fabric Marking Tools – Marking and measuring supplies

- Cutting Rollers – Alternative cutting options

- Cutting Wheels – Specialty cutting tools

- Fabric Pencils – Precision marking

- Fabric Collection – Materials for cutting projects

- Craft Supplies – General crafting materials

- Return to Homepage

Upgrade Your Cutting Workspace

Large fabric cutting boards transform workspace efficiency by providing professional-grade surfaces for precision fabric preparation. The combination of expansive work area, self-healing construction, and comprehensive measurement markings elevates cutting from basic task to refined process.

Choose board sizes appropriate for typical projects while considering available workspace and storage constraints. Invest in quality materials that provide years of reliable service through proper thickness, construction, and self-healing capacity.

Ready to expand your cutting capabilities with professional surfaces designed for serious fabric work? Explore our selection of large cutting boards and discover how the right foundation improves every quilting and sewing project you undertake.