Cutting Mat: Self-Healing Rotary Cutting Mats for Sewing

Professional Self-Healing Cutting Boards with Grid Lines for Quilting, Sewing & Craft Projects

Cutting mats protect work surfaces while providing accurate measurement grids and angle guides essential for precision fabric cutting in quilting, sewing, and crafting projects. Self-healing surfaces automatically close after rotary cutter passes preserving smooth cutting capability through thousands of cuts without permanent grooves or damage accumulating over time.

Professional crafters and casual sewers alike depend on quality cutting mats providing stable non-slip foundations for accurate fabric preparation. The grid lines, angle markings, and durable construction transform ordinary cutting tasks into precise operations ensuring accurate measurements and clean cuts critical for professional-quality finished projects.

Understanding Self-Healing Cutting Mat Technology

Self-healing cutting mats feature specialized multi-layer construction allowing surfaces to close automatically after rotary blade passes preventing permanent groove formation.

The technology relies on multiple vinyl or PVC layers with different hardness levels creating surface tension that draws cut fibers back together.

How Self-Healing Works

When rotary blades slice through mat surfaces, compressed polymer molecules spring back to original positions after blade passes closing cuts invisibly.

This self-repair capability extends mat lifespan dramatically compared to non-healing surfaces that develop permanent grooves after repeated cutting operations.

Quality mats feature 3-5 distinct layers each serving specific purposes from providing stability through enabling self-healing surface characteristics.

Layer Construction

Bottom layers provide rigid stability preventing mat flexing during cutting while middle layers absorb blade impact protecting work surfaces underneath.

Top cutting surfaces feature specialized polymer formulations optimized for rotary blade compatibility and self-healing performance after thousands of cuts.

Multi-layer construction also prevents warping from temperature changes and humidity exposure maintaining flat surfaces essential for accurate cutting.

Benefits for Fabric Work

Rotary cutters maintain sharp edges longer when used on self-healing mats compared to hard surfaces that dull blades rapidly.

The slight grip of quality cutting mat surfaces holds fabric stationary during cutting preventing shifting that causes inaccurate cuts and wasted material.

Even pressure distribution across cutting surfaces ensures consistent blade penetration creating clean edges without fraying or distortion throughout fabric layers.

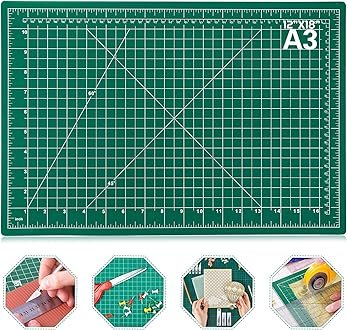

Anezus Self-Healing Sewing Cutting Mat 12×18 Inch

Double-sided rotary cutting mat featuring 5-ply construction providing professional-grade self-healing surface protecting work areas during fabric cutting, quilting, and craft projects. The 12×18 inch size offers portable convenience while dual-sided design extends usability with measurement grids on both surfaces. Compatible with rotary cutters and straight blades maintaining blade sharpness through specialized surface composition ideal for sewers, quilters, and crafting enthusiasts.

- Self-healing surface protects work areas

- Double-sided 5-ply construction

- 12×18 inch portable size

- Compatible with rotary and straight blades

- Maintains blade sharpness longer

- Grid measurements on both sides

- Ideal for sewing, quilting, crafts

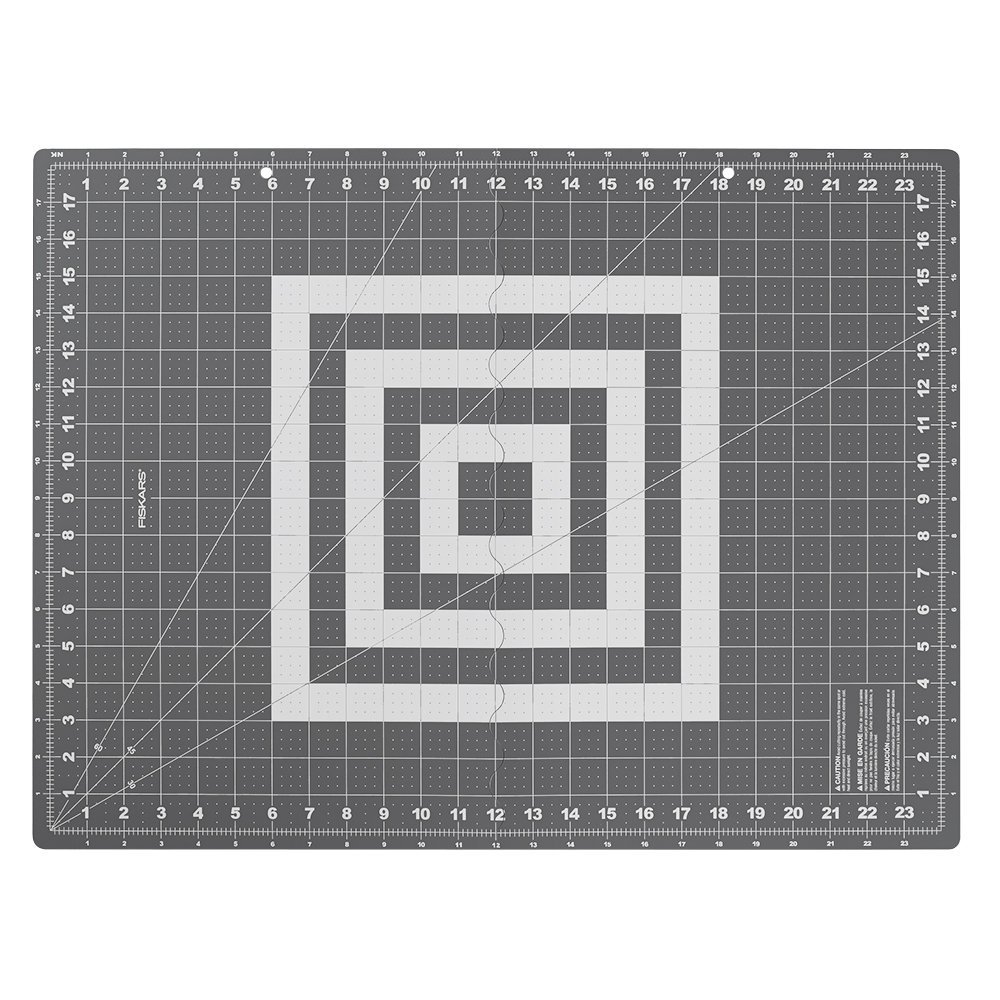

Fiskars Self-Healing Cutting Mat 18×24 Inch with Grid

Professional quilting and sewing mat featuring easy-to-read measurement grids with 30, 45, and 60-degree bias angle lines simplifying precise fabric cutting directly from bolts. The 18×24 inch surface accommodates full-width fabric cutting while self-healing technology ensures long-lasting performance through repeated use. Trusted Fiskars quality provides reliable foundation for quilting projects, arts and crafts, and general sewing applications requiring accurate measurements and clean cuts.

- 18×24 inch professional size

- Self-healing surface technology

- Easy-to-read measurement grids

- 30, 45, 60-degree bias angle lines

- Accommodates full-width fabric

- Trusted Fiskars quality

- Perfect for quilting and sewing

Choosing the Right Cutting Mat Size

Selecting appropriate cutting mat dimensions balances workspace constraints with project requirements ensuring adequate cutting area without overwhelming limited surfaces.

Standard Size Options

Small mats (12×18 inches) provide portable solutions perfect for classes, retreats, or compact sewing spaces where full-size mats won’t fit.

Medium mats (18×24 inches) represent popular all-purpose sizes accommodating most fabric cutting needs while fitting standard work tables comfortably.

Large mats (24×36 inches) suit serious quilters cutting full fabric widths directly from bolts minimizing refolding and repositioning during preparation.

Workspace Considerations

Measure available work surface dimensions before purchasing ensuring cutting mat fits with adequate space remaining for fabric positioning and tool access.

Consider storage space when not in use since larger mats require dedicated storage areas or wall-mounting solutions protecting surfaces between projects.

Multiple smaller mats sometimes prove more practical than single large mat offering flexibility for different project types and easier storage management.

Project-Specific Requirements

Quilters working with fat quarters and standard fabric widths benefit from 18×24 inch or larger mats accommodating common cutting dimensions.

Garment sewers cutting pattern pieces may need larger mats accommodating full pattern piece layouts minimizing piecing and improving accuracy.

Craft projects using smaller materials work perfectly with compact mats reducing workspace requirements while providing necessary measurement references.

Grid Lines and Measurement Systems

Accurate measurement grids distinguish quality cutting mats from basic work surfaces providing essential references for precise fabric preparation and cutting.

Grid Line Features

Standard imperial measurements appear in inches with smaller increment markings typically showing eighth-inch or quarter-inch divisions for precision work.

Some mats include metric measurements alongside imperial markings accommodating international patterns and users preferring centimeter-based systems.

High-contrast grid colors ensure visibility against various fabric colors with yellow, white, or black lines offering optimal readability depending on background.

Angle Marking Systems

Diagonal lines at 30, 45, and 60-degree angles enable accurate bias cutting essential for quilting binding, triangle piecing, and garment construction.

Circular degree markings around mat edges facilitate precise angle measurements for specialized cutting techniques and pattern alignment requirements.

Intersecting grid lines create reference points for squaring fabric and aligning rulers ensuring perpendicular cuts and accurate piece dimensions.

Specialized Markings

Some cutting mats feature additional markings for common quilting dimensions like 2.5-inch strips or standard quilt block sizes streamlining repetitive cutting.

Seam allowance guides marked at standard distances from edges help maintain consistent margins throughout sewing projects.

Corner reference points assist with fabric positioning and pattern placement ensuring consistent alignment across multiple cutting operations.

Caring for Your Cutting Mat

Proper maintenance significantly extends cutting mat lifespan preserving self-healing properties and measurement accuracy through years of regular use.

Cleaning Methods

Wipe surfaces regularly with damp cloth and mild soap removing fabric lint, thread remnants, and accumulated debris that interfere with cutting.

Avoid harsh chemicals, abrasive cleaners, or excessive water that potentially damage self-healing properties or cause warping in mat layers.

For stubborn residue, use specialized cutting mat cleaners or white vinegar solutions applied gently without aggressive scrubbing damaging surfaces.

Storage Best Practices

Store mats flat preventing warping and curling that occurs when rolled or stored vertically for extended periods compromising surface flatness.

Keep mats away from direct sunlight and heat sources preventing material breakdown and measurement marking fading over time.

Avoid placing heavy objects on stored mats preventing permanent depressions or surface damage compromising self-healing capabilities permanently.

Temperature Considerations

Maintain room temperature environments for cutting mat storage since extreme heat softens materials while cold temperatures cause brittleness.

Allow mats to acclimate to room temperature before use if stored in garages or unheated spaces preventing cutting difficulty and potential damage.

Never use irons or heat sources attempting to flatten warped mats as heat destroys self-healing properties irreversibly.

Using Cutting Mats with Rotary Cutters

Cutting mats and rotary cutters function together as integrated systems maximizing efficiency and accuracy in fabric preparation for sewing projects.

Blade Compatibility

Quality self-healing mats accommodate all standard rotary blade sizes from 18mm through 60mm diameters without surface damage or performance degradation.

The specialized surface composition allows clean blade penetration while preventing dulling that occurs with hard cutting surfaces shortening blade lifespan.

Straight craft knives and cutting tools also work effectively on self-healing mats though rotary cutters provide optimal performance and efficiency.

Cutting Technique

Apply consistent downward pressure throughout cutting strokes maintaining blade contact with mat surface ensuring complete fabric penetration without gaps.

Use rulers or straight edges aligned with grid lines guiding rotary cutters for perfectly straight cuts matching measurement requirements.

Position fabric away from mat edges when possible distributing cuts across entire surface area rather than concentrating damage in limited zones.

Blade Maintenance

Replace rotary blades showing signs of dullness including skipped threads, fabric pulling, or requiring excessive pressure during cutting operations.

Clean blades regularly removing accumulated lint and residue that interferes with smooth cutting action and accelerates blade deterioration unnecessarily.

Proper mat usage extends blade life significantly reducing replacement frequency and associated costs compared to cutting on inappropriate surfaces.

Double-Sided Cutting Mat Benefits

Double-sided mats featuring measurement grids on both surfaces provide extended usability and specialized functions depending on project requirements.

Extended Surface Life

Rotating mat periodically between sides distributes cutting wear across both surfaces doubling effective lifespan compared to single-sided alternatives.

When one surface shows excessive wear or damage, flip mat to fresh side maintaining optimal cutting performance without immediate replacement necessity.

This cost-effectiveness makes double-sided mats particularly valuable for high-volume sewers and professional quilters conducting frequent cutting operations.

Different Grid Systems

Some double-sided mats feature imperial measurements on one side and metric on reverse accommodating different pattern systems without multiple mat purchases.

Alternative configurations include standard grid on one side and specialized markings for specific techniques like bias cutting on reverse surface.

Color-coded sides using different background colors help distinguish between measurement systems or project types preventing confusion during complex work.

Versatility Advantages

Dedicate each side to specific project types keeping one surface pristine for precision work while using reverse for rougher cutting applications.

The flip capability allows quick transitions between different measurement needs without searching for alternative mats during multi-phase projects.

Double-sided construction also provides increased thickness and stability improving overall cutting experience through enhanced rigidity and surface tension.

Preventing and Fixing Mat Warping

Warping represents common cutting mat problem compromising surface flatness essential for accurate cutting but often proves preventable through proper care.

Warping Causes

Heat exposure from direct sunlight, radiators, or storage in hot vehicles causes uneven material expansion leading to permanent surface distortion.

Improper storage including rolling mats or leaning vertically against walls creates stress patterns resulting in curved surfaces over time.

Moisture exposure or humidity fluctuations cause material expansion and contraction cycles eventually producing warped surfaces losing flatness permanently.

Prevention Strategies

Store mats flat in climate-controlled environments away from temperature extremes and direct sunlight preserving original surface geometry indefinitely.

Transport mats flat when possible using protective covers or cases preventing stress during movement between locations and storage areas.

Avoid leaving mats in vehicles or near heating/cooling vents where temperature variations accelerate material degradation and warping development.

Addressing Existing Warping

Place warped mat flat under heavy books or boards for several days allowing gradual relaxation returning surface toward original flatness.

Some users successfully restore flatness by placing mat between towels and applying weight while material gradually adjusts to flat position.

Severe warping proving resistant to flattening attempts typically indicates permanent damage requiring mat replacement for optimal cutting performance.

Specialty Cutting Mats

Beyond standard self-healing mats, specialized versions offer enhanced features targeting specific crafting disciplines and advanced user requirements.

Rotating Cutting Mats

Rotating bases beneath cutting surfaces allow mat spinning rather than fabric repositioning reducing handling and improving cutting accuracy significantly.

These mats particularly benefit quilters working with complex piecing patterns requiring multiple angle cuts without constant fabric manipulation.

The rotating mechanism typically features locking positions maintaining stability during actual cutting while enabling easy repositioning between cuts.

Translucent Mats

Semi-transparent cutting mats enable pattern tracing and alignment visualization impossible with opaque surfaces facilitating certain specialized techniques.

These mats suit appliqué work, pattern drafting, and craft applications requiring visual reference to underlying templates or design elements.

Light boxes used beneath translucent mats illuminate patterns clearly making tracing operations easier during complex design transfer processes.

Folding Travel Mats

Portable mats featuring fold lines or hinged construction enable compact transport to classes, retreats, and sewing groups without cumbersome carrying.

While fold lines create slight surface disruption, quality travel mats maintain adequate flatness for accurate cutting during mobile sewing activities.

These mats typically sacrifice some size for portability offering acceptable working surfaces when transporting full-size mats proves impractical.

Pro Tip: Extend your cutting mat’s lifespan by rotating it 90 degrees every few months. This distributes wear patterns across different areas preventing concentrated damage in frequently-used zones. Mark one corner with tape helping track rotation ensuring even wear distribution maximizing mat longevity before replacement becomes necessary.

Cutting Mat Lifespan and Replacement

Understanding expected cutting mat lifespan helps budget for replacements while recognizing signs indicating performance degradation requiring new mat purchases.

Expected Longevity

Quality self-healing mats typically provide 3-5 years of regular use before self-healing properties diminish noticeably affecting cutting performance.

Professional sewers and quilters conducting high-volume cutting may need replacement every 1-2 years depending on usage intensity and maintenance practices.

Occasional crafters with careful storage habits sometimes extend mat life beyond 5 years maintaining adequate performance for periodic project requirements.

Replacement Indicators

Visible permanent grooves appearing after cutting indicate self-healing failure requiring replacement for optimal cutting accuracy and blade preservation.

Faded or illegible measurement markings compromise accuracy forcing constant ruler references diminishing efficiency benefits quality mats provide.

Surface hardening or brittleness developing over time reduces grip holding fabric stationary during cutting increasing mistakes and material waste.

Maximizing Value

Purchase quality mats from reputable manufacturers initially despite higher costs since superior construction provides better long-term value than cheap alternatives.

Follow proper care guidelines consistently maximizing lifespan through appropriate cleaning, storage, and usage patterns extending replacement intervals significantly.

Consider mat size carefully avoiding oversized purchases for limited needs since larger mats cost more while potentially showing wear before full surface utilization.

Using Cutting Mats for Different Crafts

While primarily associated with sewing and quilting, cutting mats serve numerous crafting disciplines providing protective surfaces and measurement references.

Paper Crafting Applications

Scrapbookers and card makers use cutting mats protecting work surfaces during detailed cutting while measurement grids ensure accurate paper dimensions.

The self-healing properties accommodate craft knives and precision cutting tools used in paper arts maintaining smooth surfaces through delicate operations.

Grid lines facilitate straight cuts and right angles critical for professional-looking paper craft projects requiring precise measurements and clean edges.

Leather and Vinyl Work

Leather crafters appreciate cutting mat durability withstanding thicker materials and heavier cutting pressure required for dense material penetration.

The measurement grids assist with pattern piece cutting and strap width consistency important in leather goods construction and vinyl upholstery work.

Quality mats protect expensive work surfaces from craft knife damage while providing stable foundations for accurate material cutting and preparation.

Model Building and Hobbies

Model builders use cutting mats for precision cutting of plastic, wood, and foam components requiring accurate dimensions and clean edges.

The measurement references facilitate scale calculations and component sizing essential in detailed model construction across various hobby disciplines.

Self-healing surfaces accommodate hobby knives and specialized cutting tools maintaining optimal performance through intricate detail work over extended periods.

Frequently Asked Questions

Self-healing cutting mats feature multi-layer construction with specialized polymer surfaces that automatically close after rotary blade or knife passes. The compressed molecules spring back to original positions closing cuts invisibly preventing permanent groove formation. This technology dramatically extends mat lifespan allowing thousands of cuts without surface degradation while protecting rotary blades from dulling caused by hard cutting surfaces.

Most quilters find 18×24 inch or 24×36 inch mats optimal for standard quilting projects accommodating fat quarters and fabric-from-bolt cutting. The 18×24 size suits average work spaces while providing adequate area for most cutting needs. Serious quilters working with full fabric widths benefit from 24×36 inch mats minimizing repositioning during cutting operations though requiring larger work surfaces and storage areas.

Clean cutting mats with damp cloth and mild soap removing accumulated fabric lint, thread, and debris that interfere with cutting performance. Avoid harsh chemicals, abrasive cleaners, or excessive water that damage self-healing properties. For stubborn residue use white vinegar solutions or specialized cutting mat cleaners applied gently without aggressive scrubbing. Allow mats to air dry completely before use maintaining surface integrity.

Cutting mats warp from heat exposure including direct sunlight, storage near radiators, or leaving in hot vehicles causing uneven material expansion. Improper storage like rolling mats or leaning vertically creates stress patterns producing curved surfaces. Prevent warping by storing mats flat in climate-controlled environments away from temperature extremes. Address existing warping by placing mat flat under heavy objects for several days allowing gradual surface relaxation.

Quality self-healing mats accommodate all standard rotary cutter blades from 18mm through 60mm diameters plus straight craft knives without surface damage. The specialized surface composition allows clean blade penetration while preventing dulling. Avoid serrated blades or extremely dull blades requiring excessive pressure that potentially damage self-healing properties permanently compromising mat performance and longevity.

Quality self-healing cutting mats typically last 3-5 years with regular use before self-healing properties diminish noticeably. Professional sewers conducting high-volume cutting may need replacement every 1-2 years. Proper care including flat storage away from heat, regular cleaning, and rotation between sides for double-sided mats extends lifespan significantly. Replace mats showing permanent grooves, faded markings, or surface hardening compromising cutting performance.

Yes, double-sided cutting mats provide excellent value by doubling effective lifespan through wear distribution across both surfaces. When one side shows excessive wear flip to fresh surface maintaining optimal performance without immediate replacement. Many double-sided mats feature different measurement systems (imperial and metric) or specialized markings on each side adding versatility. The increased thickness also provides enhanced stability improving overall cutting experience.

Related Resources

- Sewing Supplies – Complete sewing tools and materials

- Quilting Supplies – Everything for quilting projects

- Quilting Rulers – Precision measuring tools

- Fabric Collection – Complete fabric selection

- Fabric Irons – Pressing equipment

- Crafts Collection – General crafting supplies

- Sewing Machines – Machine options

- Sewing Scissors – Cutting tools

- Quilting Thread – Thread selection

- Return to Homepage

Protect Your Work Surface with Quality Cutting Mats

Cutting mats transform fabric preparation from challenging guesswork into precise operations through accurate measurement grids, self-healing surfaces, and stable cutting foundations. The specialized multi-layer construction protects work surfaces while extending rotary blade lifespan through surface compositions preventing premature dulling and damage. Quality mats represent essential investments for anyone serious about sewing, quilting, or crafting requiring accurate cutting and professional-quality results.

Proper mat selection considering size requirements, grid systems, and intended applications ensures optimal performance for specific project needs. Understanding care requirements including flat storage, appropriate cleaning methods, and usage techniques maximizes lifespan potentially providing years of reliable service. The measurement references, angle guides, and consistent cutting surfaces these mats provide justify their place among fundamental tools every sewing room requires for efficient productive work.

Ready to upgrade your cutting capabilities? Explore our complete sewing supplies including cutting mats, rotary tools, and measuring equipment, or discover quilting supplies complementing mat usage for comprehensive project preparation ensuring accurate professional results across diverse creative applications.