Fabric Gems: Complete Guide to Rhinestones and Crystals for Clothing and Crafts

Application Methods, Adhesive Selection, and Durable Techniques for Sparkling Embellishments

Fabric gems transform ordinary textiles into sparkling creations through rhinestones, crystals, and jeweled embellishments that catch light and add dimension. These versatile decorative elements work on everything from clothing and accessories to home decor, offering instant glamour without advanced sewing skills.

Understanding proper application techniques and adhesive selection ensures gems stay securely attached through washing and wear. The right materials and methods create professional-looking embellishments that last years rather than falling off after first use.

What Makes Fabric Gems Different

Fabric gems consist of faceted crystals or rhinestones specifically designed for textile attachment through adhesives, heat transfer, or sewing. These embellishments feature flat backs enabling secure contact with fabric surfaces unlike jewelry stones with pointed backs.

The specialized construction distributes light through precisely cut facets creating sparkle and brilliance impossible with flat decorations. Quality gems maintain their clarity and shine through repeated washing when properly attached using appropriate methods.

Types of Fabric Gems

Glass crystals offer superior sparkle and durability with Swarovski representing the premium standard for high-end projects. These authentic crystals feature precise faceting and coatings producing exceptional light reflection valued in bridal wear and formal garments.

Acrylic rhinestones provide budget-friendly alternatives for casual projects, children’s crafts, and temporary embellishments. While less brilliant than glass options, quality acrylic gems still create attractive sparkle at significantly lower cost.

Resin flatback gems combine affordability with decent clarity, working well for practice projects and large-area coverage. These lightweight options reduce bulk on garments while maintaining reasonable sparkle for everyday wear.

Understanding Gem Measurements

Fabric gems use millimeter sizing or “ss” notation indicating stone size with larger numbers representing bigger gems. Common sizes range from 2mm (ss6) for delicate accent work to 6mm (ss30) for bold statement pieces.

Selecting appropriate gem size depends on project scale and viewing distance with smaller stones suited for intricate patterns and larger gems effective for bold designs. Mixing sizes within single projects creates visual interest and depth enhancing overall sparkle effect.

Choosing the Right Application Method

Different attachment methods suit varying project requirements, durability needs, and fabric types. Understanding options ensures optimal results without wasted effort or premature gem loss.

Adhesive Application Techniques

E6000 industrial-strength adhesive provides superior bonding for permanent installations withstanding washing and regular wear. This flexible formula moves with fabric preventing gems from popping off when material bends or stretches.

Fabric-specific glues like Aleene’s Jewel-It offer moderate hold perfect for items receiving gentle use. These water-based formulas dry clear and remain flexible making them ideal for delicate fabrics or children’s projects.

Gem adhesive application requires precision with small dots applied to flat gem backs rather than fabric surfaces. This technique prevents glue bleed-through and ensures clean installation without visible adhesive residue.

Heat Transfer Installation

Hot-fix rhinestones feature heat-activated adhesive backing bonding to fabric when heated with specialized tools or household irons. These gems install quickly enabling complex pattern application in fraction of time required for individual gluing.

Heat setting tools with flat tips press against gems applying consistent temperature activating adhesive without scorching fabric. Standard household irons work for larger areas when used without steam at appropriate temperature settings.

Proper heat transfer requires 320-350°F temperatures applied for 10-20 seconds per gem depending on fabric type. Natural fibers tolerate higher heat than synthetics which may melt or scorch under excessive temperatures.

Sewing Attachment Method

Sew-on gems with pre-drilled holes provide most permanent attachment through needle and thread. This traditional method suits items receiving heavy wear or frequent washing where adhesive might eventually fail.

Thread selection matching either gem color or fabric background determines whether stitching appears visible or hidden. Small sharp needles facilitate work on tightly woven materials while beading needles handle multiple-hole gems efficiently.

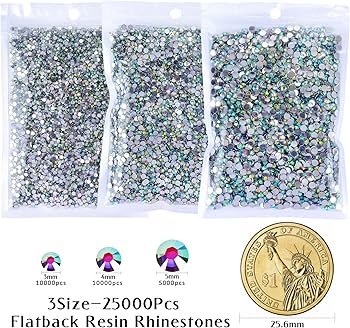

25000 Piece Resin Rhinestone Craft Kit

Comprehensive rhinestone kit containing 25000 pieces of clear resin flatback gems in five sizes from 2mm to 6mm with professional application tools. The organized 24-grid storage box separates sizes for easy access while included tweezers, pickup pen, and three 10ml bottles of B7000 jewelry glue provide everything needed for immediate project start.

- 25000 clear resin rhinestones

- Five sizes: 2mm to 6mm

- 24-grid organized storage

- Precision tweezers included

- Pickup pen for small gems

- Three B7000 glue bottles

- Professional jewelry adhesive

Hotfix Rhinestone Applicator Tool Kit

Professional bedazzler kit featuring hot-fix applicator wand with 5000 pieces of AB crystal and clear rhinestones in three sizes for clothing and craft embellishment. The heated wand tip activates pre-applied adhesive backing on gems creating secure bonds on fabric, denim, leather, and other materials without separate glue application.

- 5000 hotfix rhinestones included

- AB crystal and clear gems

- Three different sizes

- Electric heating wand

- Pre-applied adhesive backing

- Works on multiple materials

- No separate glue needed

Best Fabrics for Gem Application

Medium-weight stable fabrics like cotton, denim, and canvas provide ideal surfaces for gem attachment supporting weight without excessive movement. These materials accept all application methods from adhesives to heat transfer to sewing.

Stretch fabrics including jersey and spandex require flexible adhesives that accommodate material movement without gem detachment. Heat-transfer gems work particularly well on these materials as activated adhesive bonds flexibly with fabric structure.

Preparing Fabric Surfaces

Clean fabric thoroughly before gem application removing oils, dirt, and sizing that prevent proper adhesive bonding. Washing and drying new materials ensures optimal surface conditions for secure attachment.

Lightweight fabrics benefit from interfacing reinforcement at gem placement areas preventing tear-through under stress. Fusible interfacing applied to fabric wrong side strengthens material without visible changes to appearance.

Mark gem positions using water-soluble fabric markers or chalk ensuring accurate placement before permanent attachment. Careful planning prevents uneven spacing and allows design adjustments before committing to final installation.

Working with Delicate Materials

Silk, chiffon, and organza require minimal adhesive application avoiding bleed-through on sheer or lightweight structures. Apply glue to gem backs rather than fabric and use smallest effective amounts for secure bonding.

Sewing provides safest attachment method for irreplaceable or antique textiles using finest needles and silk thread. This reversible technique allows future gem removal without permanent fabric damage if needed.

Creating Effective Gem Patterns

Simple linear arrangements along necklines, hems, or seams offer elegant embellishment for beginners. Straight lines forgive placement errors while creating clean professional appearance suitable for formal and casual garments.

Scattered random placement mimics starlight or snowfall creating organic sparkle across fabric surfaces. This forgiving technique requires no precise measuring while producing attractive results on everything from t-shirts to formal wear.

Advanced Design Techniques

Ombre effects transitioning from dense gem concentration to sparse placement add visual movement and sophistication. Gradual density changes create focal points drawing eyes to specific garment areas like shoulders or waistlines.

Geometric patterns including circles, triangles, and chevrons suit contemporary fashion aesthetics. These structured designs benefit from careful planning using templates or stencils ensuring clean lines and consistent spacing.

Floral and vine motifs bring organic beauty to garments and accessories through flowing curved arrangements. These naturalistic patterns work beautifully on feminine designs and wedding attire adding romantic sparkle.

Planning Complex Designs

Sketch patterns on paper before fabric application allowing design experimentation without permanent commitment. Transfer approved designs to fabric using water-soluble markers providing placement guides during installation.

Calculate gem quantities by counting pattern requirements then adding 10-15% extra for mistakes and future repairs. Purchasing adequate supply prevents mid-project shortages requiring color or size matching later.

Durability and Maintenance Considerations

Properly applied gems using quality adhesives last years through regular wear and washing when care instructions are followed. Turn garments inside out before machine washing protecting gems from agitation and friction with drum surfaces.

Cold water gentle cycles preserve both gem attachment and fabric integrity better than hot water or aggressive washing. Air drying prevents heat exposure that may soften adhesives or damage certain gem coatings.

Maximizing Gem Longevity

Allow 24-48 hours curing time after adhesive application before wearing or washing embellished items. This complete cure period ensures maximum bond strength preventing premature gem loss.

Store gemmed garments flat or on padded hangers avoiding pressure on embellished areas. Hanging inside out prevents gems from snagging other garments or surfaces during storage.

Inspect gems periodically for loosening addressing issues before complete detachment occurs. Small amounts of original adhesive reapplied to loose edges restores secure attachment preventing gem loss.

Repairing Detached Gems

Clean both gem and fabric area before reattachment removing old adhesive residue and debris. Fresh adhesive applied to clean surfaces bonds more securely than application over contaminated areas.

Keep extra gems in original colors and sizes for replacement of lost stones. Exact matches maintain pattern integrity while mismatched replacements may appear obvious depending on design density.

Popular Gem Project Applications

Clothing embellishment ranges from subtle accent details to full-coverage designs transforming basic garments into statement pieces. Necklines, cuffs, and pocket edges receive elegant enhancement through strategic gem placement.

Dance and performance costumes benefit from maximum sparkle catching stage lighting through extensive gem coverage. These high-visibility applications demand secure attachment withstanding energetic movement and frequent wear.

Accessory Embellishment

Handbags and purses gain personality through gem accents on flaps, closures, or decorative panels. Structured bag surfaces provide stable bases for adhesive application supporting gem weight effectively.

Footwear transformation occurs through gems placed on heels, sides, or upper portions avoiding high-wear toe and sole areas. Industrial-strength adhesives ensure gems remain attached through walking stress and ground contact.

Hair accessories including headbands, clips, and barrettes sparkle with strategic gem placement. These small items accommodate elaborate designs visible at close range during wear.

Home Decor Applications

Throw pillows receive glamorous updates through gem embellishment on front panels or corners. These decorative accents withstand less stress than clothing allowing more delicate attachment methods.

Table linens for special occasions gain festive sparkle through scattered gem placement. These temporary embellishments may use less permanent adhesives suitable for single-event use.

Pro Tip: Always apply adhesive to gem backs rather than fabric surfaces to prevent glue bleed-through and staining. This technique ensures clean installations with invisible bonding and professional appearance.

Essential Tools for Gem Application

Fine-tipped tweezers enable precise gem placement and adjustment during installation. Jeweler’s tweezers with flat tips grip small stones without scratching or damaging faceted surfaces.

Precision adhesive applicators control glue flow preventing excess application that creates messy installations. Fine-tipped bottles or syringe applicators deliver exact amounts needed for secure bonding.

Specialized Equipment

Heat setting tools with temperature control ensure proper hot-fix activation without fabric damage. These specialized wands feature flat tips pressing evenly against gems during heat application.

Gem sorting containers with multiple compartments organize stones by size and color for efficient workflow. Clear compartments allow quick visual identification speeding project completion.

Bright adjustable lighting reveals true gem and fabric colors while reducing eye strain during detailed work. Natural spectrum bulbs provide accurate color matching for professional results.

Workspace Organization

Shallow dishes or bead trays hold working quantities of gems preventing spills across work surfaces. These containers keep current stones accessible while protecting bulk supplies from contamination.

Water-soluble fabric markers enable temporary design marking that washes away after installation. These specialty markers provide visible guides without permanent fabric staining.

Working with Special Fabrics

Leather and vinyl require specialized adhesives formulated for non-porous surfaces. Standard fabric glues may not bond effectively to these materials necessitating leather-specific products.

Waterproof or coated technical fabrics resist standard adhesive bonding requiring industrial-strength options. Testing on inconspicuous areas determines compatibility before full project application.

Stretch Material Considerations

Athletic wear and activewear fabrics demand flexible attachment methods accommodating extreme stretching. Heat-transfer gems with elastic bonding properties work better than rigid adhesives on these materials.

Swimwear embellishment requires waterproof adhesives maintaining bonds through chlorine and saltwater exposure. Marine-grade adhesives offer superior water resistance compared to standard fabric glues.

Textured Surface Solutions

Heavily textured fabrics like boucle or terry cloth may not provide smooth surfaces for effective gem attachment. Creating smooth appliqué patches for gem mounting then attaching patches to textured fabrics solves this challenge.

Sequined or beaded fabrics require gem placement in smooth areas between existing embellishments. Overcrowding creates visual confusion while thoughtful spacing enhances both original and new decorations.

Safety and Best Practices

Work in well-ventilated areas when using industrial-strength adhesives releasing fumes during application and curing. Open windows or use fans preventing harmful vapor concentration in workspace.

Protect work surfaces with disposable coverings preventing adhesive damage to furniture. Wax paper or plastic sheeting provides non-stick barriers between projects and tables.

Child Safety Considerations

Supervise young children during gem projects preventing choking hazards from small stones. Large gems and washable glues provide safer alternatives for elementary-age crafters.

Store small gems and toxic adhesives securely between sessions preventing unauthorized access. Lockable containers or high shelves keep materials away from unsupervised young hands.

Heat Application Safety

Exercise caution with hot tools preventing burns during heat-transfer application. Allow adequate cooling time before touching gems or surrounding fabric areas after heating.

Test heat settings on fabric scraps before applying to final projects preventing scorching or melting. Different materials tolerate varying temperatures requiring individual assessment.

Frequently Asked Questions

E6000 industrial-strength adhesive provides the most durable bonding for permanent fabric gem installations withstanding washing and regular wear. This flexible formula moves with fabric preventing gems from popping off when material bends or stretches. For delicate fabrics or children’s projects, fabric-specific glues like Aleene’s Jewel-It offer moderate hold with water-based formulas that dry clear and remain flexible without harsh fumes.

Yes, properly applied fabric gems withstand washing when appropriate techniques and adhesives are used. Turn garments inside out before machine washing, use cold water gentle cycles, and air dry to maximize gem retention. Allow 24-48 hours curing time after initial application before first washing. Sewn-on gems offer most permanent attachment for items receiving frequent washing while quality adhesives and heat-transfer methods also provide good durability with proper care.

Apply hotfix rhinestones by positioning them on fabric then pressing with heat setting tool or household iron at 320-350°F for 10-20 seconds. The heat activates pre-applied adhesive backing bonding gems to fabric as it cools. Use specialized applicator wands for individual gem placement or flat irons without steam for larger pattern areas. Allow complete cooling before handling to ensure proper adhesive setting and maximum bond strength.

Medium-weight stable fabrics like cotton, denim, and canvas work best for gem application providing adequate structure to support weight without excessive movement. These materials accept all attachment methods including adhesives, heat transfer, and sewing. Stretch fabrics require flexible adhesives or heat-transfer gems accommodating material movement. Delicate fabrics like silk need minimal adhesive or sewing methods while heavily textured materials may require smooth appliqué bases for effective gem attachment.

Fabric gems are not typically reusable after adhesive or heat-transfer application as removal damages both gems and adhesive backing. Sewn-on gems can potentially be removed and reused if thread is carefully cut without damaging gems or mounting holes. Self-adhesive gems may allow repositioning immediately after placement but lose tackiness preventing future reuse. For temporary applications requiring removal, consider clip-on gem accessories or loosely tacked gems using minimal thread that removes easily.

Properly applied fabric gems using quality materials last several years through regular wear and washing. Sewn-on gems provide longest lifespan often remaining secure indefinitely when thread stays intact. High-quality adhesive applications last 2-5 years with proper care while heat-transfer gems typically maintain bonds for 1-3 years. Longevity depends on application quality, adhesive type, washing frequency, and stress level gems endure during use.

Never iron directly over fabric gems as heat can melt adhesives, damage gem coatings, or crack crystals. Turn garments inside out before ironing or use pressing cloth between iron and embellished areas for protection. Steam should be avoided as moisture may weaken adhesive bonds. If ironing near gems is unavoidable, use lowest effective temperature and minimal contact time. For heat-set gems during initial application, follow specific temperature and duration guidelines for proper installation.

Transform Fabrics with Sparkling Embellishments

Fabric gems provide accessible embellishment options transforming ordinary textiles into eye-catching creations through strategic sparkle placement. Understanding application methods, adhesive selection, and proper techniques ensures professional results lasting through years of use and enjoyment.

Whether creating formal wear, updating casual clothing, or personalizing accessories, quality materials and careful installation produce durable embellishments worthy of creative investment. Proper fabric preparation, tool selection, and attachment methods determine success difference between disappointing gem loss and lasting sparkle.

Start your gem embellishment projects with confidence using proven techniques and quality supplies for spectacular results that showcase your creative vision and attention to detail.